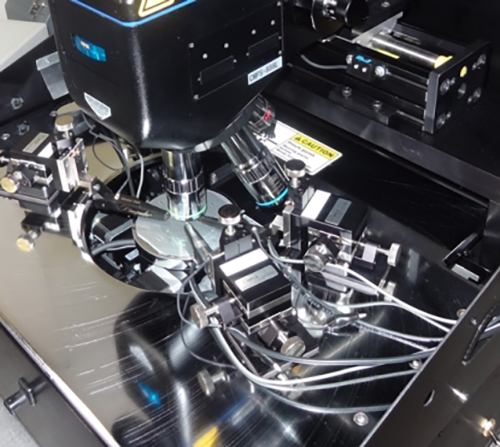

LCS- 4000 Series Analytical Probe Station with Laser Cutting System

The LCS-4000 Probe Station with Integrated Laser Cutting System gives the user maximum flexibility in semiconductor diagnostic cutting, failure analysis, trimming, marking and topside layer removal. All of these functions can be performed on a microscopic level, all on this one system, which provides a high level of performance that is remarkably easy to use.

The integrated laser cutting system can be used to alter conductors on integrated circuits by laser ablating contact leads, sacrificial layers and other materials without damage to the devise internals. This laser trimming process allows for selective layer removal, such as topside layer removal, and can aid in semiconductor failure analysis or for fine tuning device characteristics, such as resistance, capacitance or RF properties. MicroXact’s laser cutting system is also capable of isolating faulty components by cutting the metal lines that connect the faulty component to the rest of the circuit. Pre-built logic includes automated identification of faulty devices on the wafer and erasing these devices from the wafer completely via ablation.

The LCS-4000 is offered as a motorized, semi-automated or fully-automated configuration system and can easily be configured for a wide range of applications with a variety of design options and accessories available.

Additional Information

LCS-4000 Probe Station Features

- System integrates the Laser Cutting System for selectively removing material, such as topside layer removal, making high-precision cuts and marking metal.

- Designed for simultaneous DC and/or RF probing while laser trimming leads or removing defects from devices.

- Fully motorized system allows user to remotely position the sample stage, the platen and the microscope independently while the system is entirely contained in a light-tight enclosure for safe and easy operation of the system.

- Standard configuration includes independent 100 mm x 100 mm range of motion for sample stage and microscope (larger ranges available).

- Multi-axis dual joystick controller provides easy operation of all motion components and can be customized to include a variety of additional functions.

- System can be upgraded to include semi-automated control of wafer probing.

- Isolated feed-through terminals located on both sides of station for convenient connection to micropositioners can be customized for BNC, Triax, or DC pin connections.

LSC-4000 Probe Station Specifications

- LCS-4000

- LCS-4000

- The following specifications are for a standard configuration. In most cases, each LCS-4000 Probe Station system can be customized to exceed these values.

- Wafer Size

Up to 100mm (Larger sizes available)

- XY Stage Travel

Up to 100mm x 100mm (Larger range available)

- XY Stage Resolution

Motorized, several options available

- Platen Travel

12.7mm or more

- Platen Adjustment

Dual coarse and fine control

- Platen Planarity

<12.7μm across 150mm

- Platen Rigidity

<50μm for 4.5kg

- Platen Material

Chrome- plated steel

- Vacuum Chuck

Multi-zone vacuum

- Chuck Flatness

+/-13μm

- Chuck Breakdown Voltage

At least 500V

- Chuck Isolation

At least 1GΩ

- Chuck Adjustment

Motorized, +/-15° fine

- Chuck Rotation Resolution

0.01° resolution

- Microscope

High resolution Seiwa Optical

- Microscope Travel

100mm x 100mm (Larger range available)

- Number of Objectives

Up to 4

- Number of Tube Lenses

Up to 3

- Feedthrough Terminals

BNC, Triax or Banana plug

- Focusing Range

+/- 25mm

- Illuminating System

Bright field incident illuminator with aperture stop

- Laser Type

Pulsed air cooled Nd: YAG Class IIIb

- Pulse Width

3-4ns at all wavelengths

- Emission Wavelength

1064nm, 532nm, & 355nm

- Pulse Energy (High/Low)

1064nm: 0.5mJ / 0.15mJ

532nm: 0.5mJ / 0.15mJ

355nm: 0.4mJ / 0.15mJ - Cut Size (single pulse)

Min. (w/ 100X objective) 1064nm:

2μm x 2μm

532nm: 1μm x 1μm

355nm: 1μm x 1μmMax. (w/ 50X objective) 1064nm: 50μm x 50μm

532nm: 40μm x 40μm

355nm: 30μm x 30μm - Repetition Rate

Single shot, 1Hz continuous; 5Hz for 50 shots followed by 20 sec cool-down period

- Attenuation Range

>100:1 for 532nm and >40:1 for 1064nm and 355nm using HI/LO ranges

- System Dimensions

60cm wide x74cm deep x 92cm high

- System Weight

90kg to 230kg depending on options selected