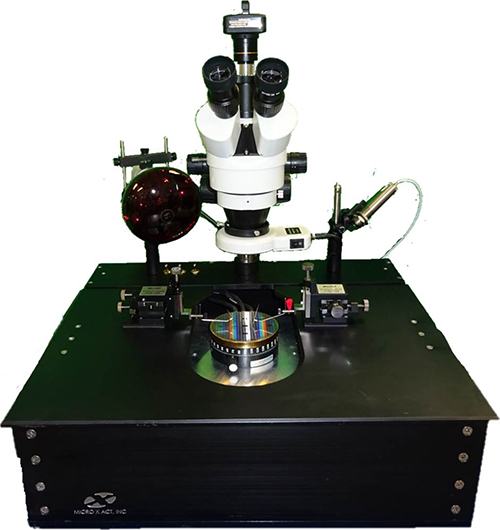

IR Seebeck Characterization Systems

The IR Seebeck Characterization Systems are capable of measuring the Seebeck coefficient and electrical resistivity of a wide range of samples. Common Seebeck characterization devices available from other companies are restricted to bridge-type in-plane samples or other limited geometries. MicroXact’s system allows you to measure cross-plane through thin-films and across complex 3D structures as well as characterizing the voltage response to an applied current. By measuring the cross-plane value of thin-film thermoelectrics, this system gives you the unique capability of measuring the thermoelectric material in the same configuration that it would be used in a device. These unique systems can be designed to be capable of measuring over extremely wide temperature ranges from below 4K to over 800K.

Specifications

- ASM-200

- ASM-200

- Wafer Size

Up to 200mm

- Sample Geometry

Thin films and 3D structures

- Non-contact Temperature Measurement

0.01K precision

Adjustable emissivity

150ms sampling interval - Infrared Heating

Up to 5000 W/m2

- Temperature Operating Range

4K-800K

- Software Control

LabView-based, Windows-compatible

- Output

Seebeck Coefficient and Electrical Resistivity/IV-Curve